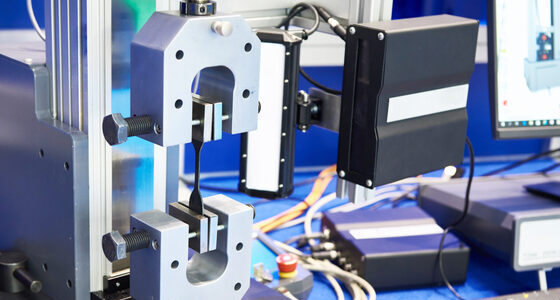

Tensile Testing

Tensile testing is a common denominator for a range of test processes that yield information about the tensile strength, yield strength, compression and ductility of the material under study. It also covers flexure tests, as well as shear and torsion tests.

A so-called Universal Testing Machine (UTM) allows for performing all tests mentioned above. This makes the UTM ideal for performing complex tasks in the field of material and component testing and the solution for demanding testing applications, whether in quality control or for research projects. In combination with climate chambers, the evolution of mechanical parameters during product lifetime can be investigated.

A UTM or tensile testing machine is also known as a tensiometer.

By means of a loadcell, the change in force is recorded that could indicate a failure or loss of strength of the specimen tested. In combination with the travelled distance of the grips, various mechanical parameters can be quantified.

A tensile testing machine is used to perform testing in accordance with several common ISO, ASTM and automotive standards, e.g. ISO 527, ASTM D412, ASTM F88, ASTM A370 and a diversity of other methods.

Ideal Uses

R&D and quality control engineers working in the field of:

- Adhesives

- Composites

- Metals/Foils

- Food

- Medical devices

- Non-wovens

- Packaging

- Paper

- Paperboard

- Plastic Film

- Rigid Plastic

- Rubber/Foam

- Polymers

- Tissue

- Textiles

Strengths

- The term “universal” in the name of the equipment reflects that it can perform many types of tensile, tension and compression tests on materials, components and structures to determine how a material reacts to the applied force.

Limitations

- Width of specimen due to dual column set-up (max. 440 mm of width)

- Restriction on elongation by height (max. 980 mm of crosshead travel distance)

- Maximum load of 20 kN applied force

Tensile Testing Technical Specifications

- ZwickRoell 20 kN all-round Universal Testing Machine

- Loadcells available in the range of 100 N, 1 kN, 20 kN, with an accuracy class of 0.5

- Crosshead speed between 0.0005 and 500 mm/min

- Specimen grips and fixtures for:

- Tensile testing

- Compression testing

- Peel testing

- Coefficient of friction testing

- Puncture testing

- 3- or 4-point flexural bending testing

- Tear testing

- Delamination testing

- …and more customized fixture options

- Specimen climate chamber for testing from -80°C up to +250°C

- Software applicable for calculation of:

- Applied force

- Tensile strength

- Young’s modules (modules of elasticity)

- Yield strength

- Break strain

- Poisson’s ratio (deformation)