Electron Backscatter Diffraction

Electron Backscatter Diffraction (EBSD) is a technique that is uniquely suited to characterize crystallographic properties of your samples. Proprieties such as: grain size, grain shape, grain orientation, grain boundary misorientation, spatial distribution of phases, local deformation and texture can all be characterized by this technique.

EBSD Analysis is a great complement to the excellent capabilities of our X-ray diffraction (XRD) services. While our XRD tools and staff can provide unparalleled information on phase ID, nanocrystalline grain size, thin film thickness and textures; the new capabilities available by EBSD will provide spatial information, help to visualize the microstructure and add to a complete description of your crystalline samples.

Ideal Uses of EBSD

- Visualization of microstructure with spatial coordinates

- Characterization of texture in exact locations such as near welds or on semiconductor bond pads

- Characterization of grain size & texture as it related to finish quality in sheet steel and Al

- Measurement of large grains, without the error associated with LM

- Characterization of special grain boundaries, such as CSL’s and twins

- Measurement of grain misorientation

- Characterization of deformation by examination of intragrain misorientation and grain aspect ratio

- Characterization of epitaxially grown thin films

- Characterization of in-depth texture, by examining cross sections

EBSD Examples

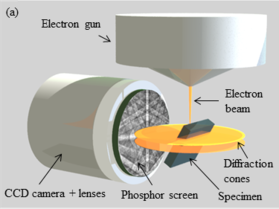

EBSD – Electron Back Scatter Diffraction is a technique using the electron beam of a SEM to differentiate the crystallographic orientations of grains on a sample surface. From EBSD we obtain:

- Grain orientation

- Grain size

- Misorientation between grains

- Pole figures and maps

Strengths

- Accurately provides spatially resolved grain size and phase information from several 10s of nm to several 10s of mm.

- Provides texture information from localized area.

- Provides grain boundary angle information.

- Can be used for failure analysis.

Limitations

- The phase information needs to be known a-priori.

- Cannot analyze amorphous materials.

- Cannot distinguish phases of similar crystal structures (need to use EDS-EBSD technique).

- High-quality polished surface is required.

EBSD Technical Specifications

- Signal Detected: Diffracted electrons

- Elements Detected: All elements, assuming they are present in a crystalline matrix

- Detection Limits: Grain size >80 nm

- Quantitative analysis: Grain size and related measurements: ~10%